We're going to talk about two fascinating technologies today that are significant in the privacy glass industry: PDLC and SPD smart glass film. But not all smart glass film technologies are created equal; each has unique qualities pertaining to cost, design, and functionality.

If you want to know what the key differences are between these smart glass films, keep reading!

Table Of Contents

1. Smart Glass

2. PDLC Technology - The Magic Behind Privacy Glass

3. SPD Smart Glass Film: Suspended Particle Devices in Action

4. Common Differences

5. FAQs

Smart Glass

Laminated glass that adjusts to the preferences of the user is called smart glass. It is made up of many layers that work together to provide the user with customizable transparency control that goes beyond what is possible with regular glass. All it takes is pressing a button to go from clear to opaque.

With their unique characteristics and applications, state-of-the-art technologies like as SPD and PDLC provide this revolutionary quality.

PDLC Technology - The Magic Behind Privacy Glass

It stands for polymer dispersed liquid crystal technology and is widely used in smart glass applications. Because it involves polymer films with dispersed liquid crystal droplets.

How To Work?

Now that you understand the basics of Smart Glass, it's time to learn about PDLC technology.

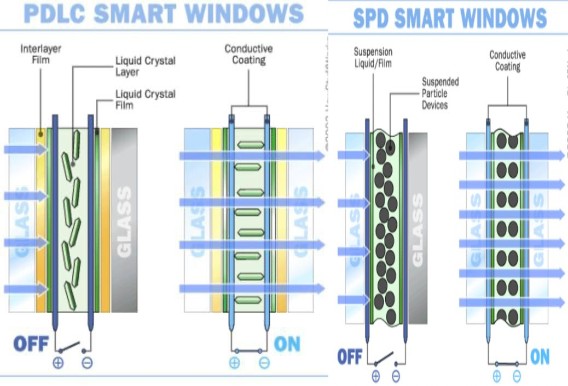

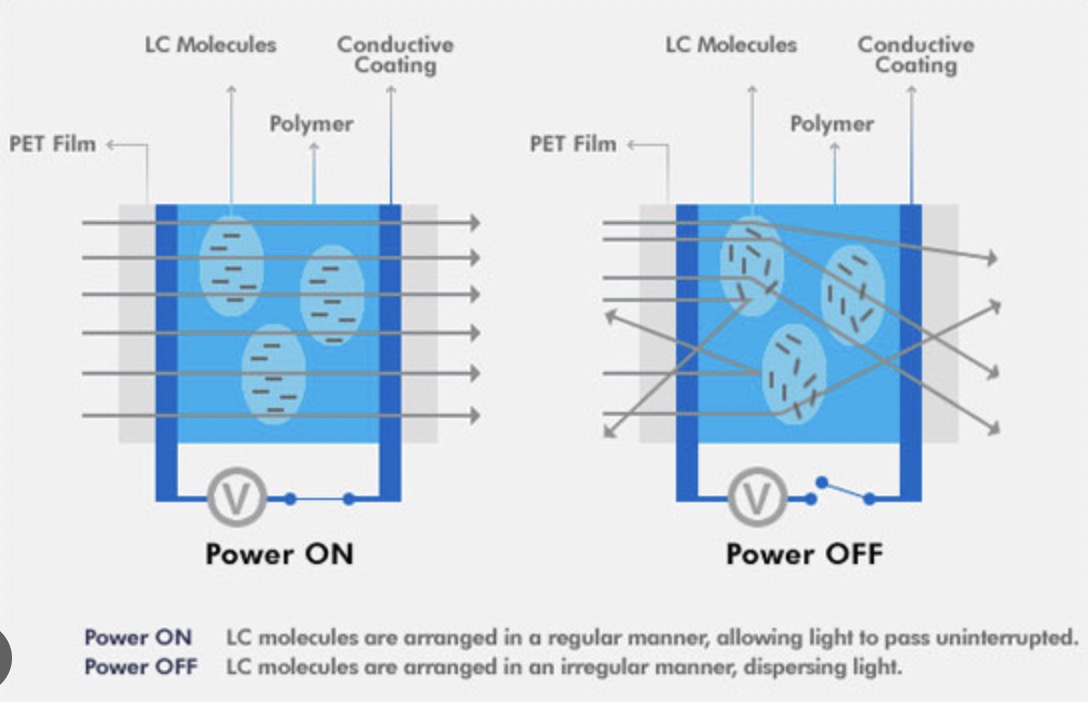

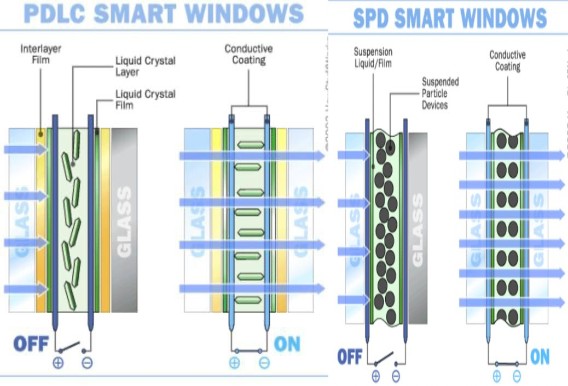

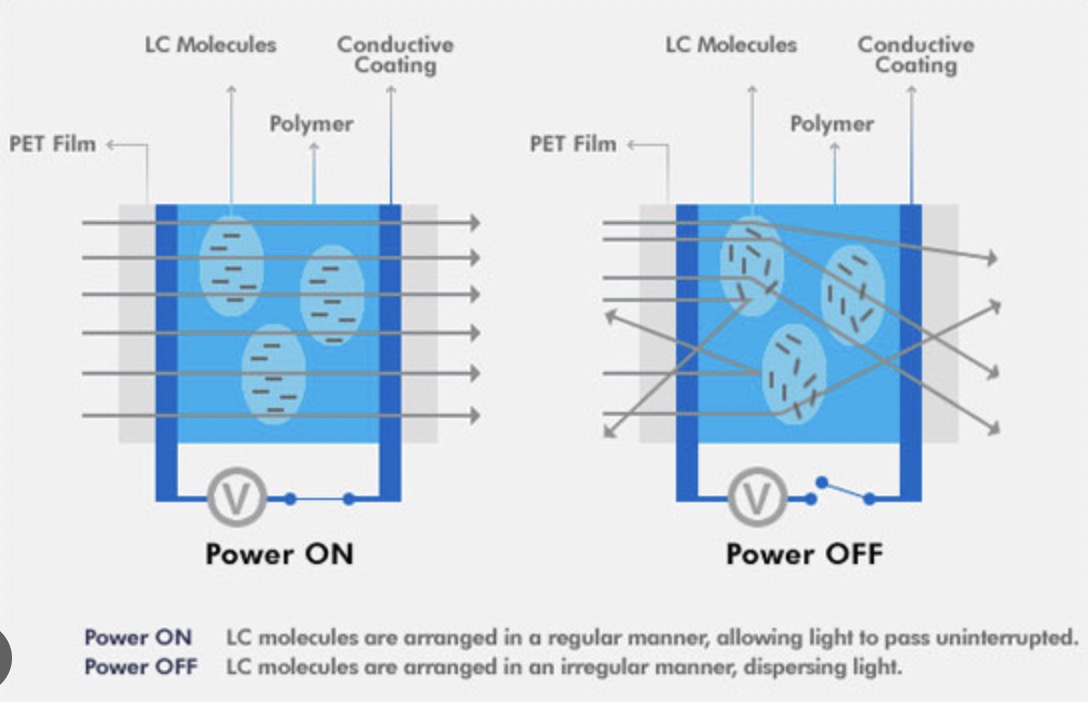

This technology utilizes liquid crystals in a polymer matrix. Because of the natural dispersion of light caused by the randomly organized liquid crystals, the glass appears opaque. The liquid crystals align when an electric current is applied, allowing light to flow through and turning the glass transparent. PDLC technology works well for privacy glass solutions because it allows for a smooth transition between transparency and opacity.

Applications Of PDLC Technology

High-tech displays, windows, and partitions are just a few of the many applications that PDLC technology is employed in. In places like conference rooms, hospitals, and residential areas—where instantaneous privacy control is crucial—it is particularly well-liked. For those searching for unique and adaptable smart glass solutions, it is the go-to option due to its ability to add interactive features and modify transparency levels.

Further information about PDLC technology applications can be discovered by exploring Taizhou's perspectives on the subject. Delving into the intricacies of PDLC can provide a deeper insight into the innovative possibilities of privacy glass.

SPD Smart Glass Film - Suspended Particle Devices In Action

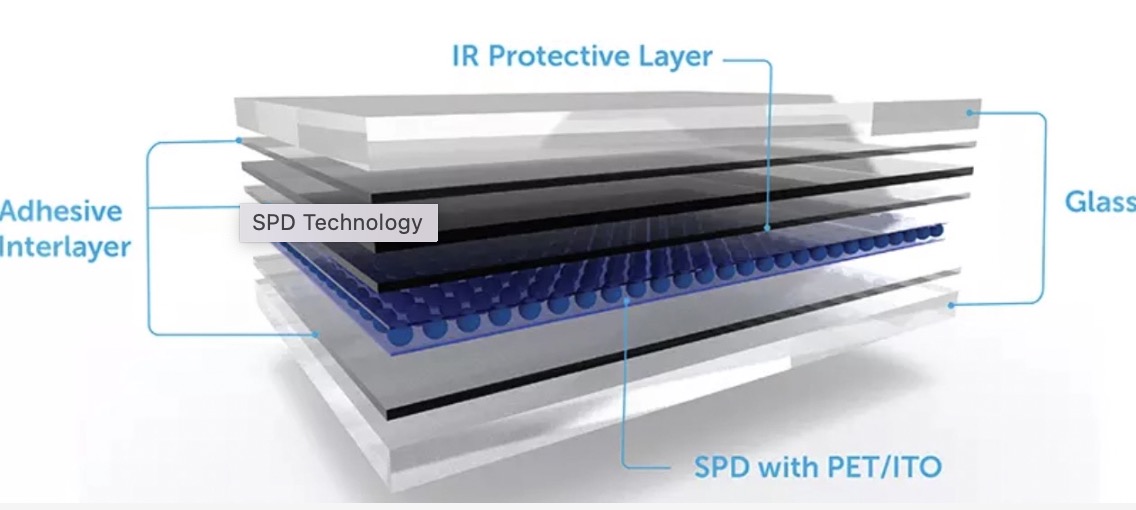

Suspended Particle Devices is an acronym for SPD. Similar to PDLC, SPD smart glass films provide privacy, but they do it in a different way. Furthermore, this technology allows for the transition between clear and tinted lenses, thus protecting against UV rays while letting in natural light.

How Do Suspended Particle Devices Work?

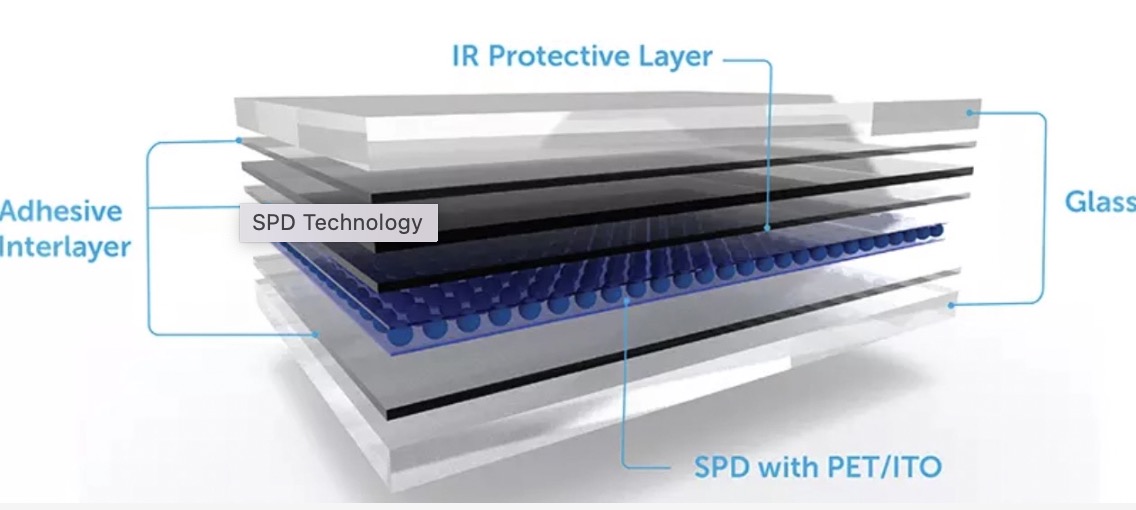

Microscopic particles suspended in a coating between glass layers enable SPD smart glass to function. Many particles in the film align when an electric charge is supplied, causing the glass to become transparent. The particles scatter when there is no charge, causing the glass to become opaque.

A seamless and quick transition from see-through to non-transparent is made possible by this method. The SPD technique is extremely reactive due to the quick alignment or dispersion of particles. This unique feature is required in applications like skylights and automobile windows where rapid shade adjustments are essential.

The strength of SPD is in its ability to quickly modify tint levels for instant comfort and privacy. Due to its effectiveness, it is now widely used in various environments.

Uses Of SPD Technology

Windows, skylights, and sunroofs on automobiles frequently use SPD smart glass. Because to its quick tint adjustment capability, people inside may feel more comfortable and the glare is reduced. While also aiming to provide instant privacy, may stand out in environments requiring fast shifts between transparency and opacity.

Common Differences

Dynamic glass solutions are enhanced with a touch of magic by smart glass technologies such as PDLC and SPD. Let's explore the nuances of their technology, including reaction times, cost considerations, durability, and applications.

1.Technology Mechanism

PDLC

In PDLC, an electric current governs the captivating arrangement of liquid crystals inside a polymer matrix. This makes the change from transparent to opaque smooth and adaptable. Recent studies have demonstrated the remarkable accuracy of PDLC technology by demonstrating its ability to achieve alignment in a matter of microseconds.

SPD

Based on the arrangement and location of microscopic suspended particles in a film encased in layers of glass, it function similarly to a microdancing performance. Particle motion and darkness level are both governed by the electric charge. Recent experiments indicate that the particle alignment in SPD happens quickly, validating its rapid transitioning ability.

2. Response Time

With a reaction time typically measured in milliseconds, PDLC smart glass film have an exact and swift transition between transparent and opaque states. Tests conducted in the field have demonstrated that its response is reliable in a variety of settings.

SPD technology is renowned for its fast reaction time, allowing for simple state transitions in a matter of seconds. Tests in the lab have shown that it is advantageous for applications that need quick changes, such as skylights or automobile windows. Because of its versatility, it is a great option for dynamic tinting solutions.

3. Cost Considerations

PDLC smart film costs can change depending on a number of variables, including application complexity, size, and customizability. While maintaining an overall affordable stance, the long-term energy savings of PDLC technology help offset the initial cost. Using PDLC can increase a building's energy efficiency, according to recent research.

A higher initial investment could be necessary for SPD smart film because to their sophisticated features and fast reaction times. However, empirical research has demonstrated that the long-term benefits—such as enhanced energy economy and glare control—may outweigh the upfront costs, especially in scenarios where dynamic tint adjustments are crucial.

4. Durability And Maintenance

PDLC smart glass film is renowned for being long-lasting and requiring little maintenance. While periodic dusting and fingerprint removal is recommended, stress testing have shown that the technology is robust. Long-term tests demonstrate that PDLC's durability stays stable, which makes it appealing for prolonged usage.

High durability and low maintenance requirements characterize SPD technology. Regular cleaning with a soft cloth and mild detergent is recommended to preserve peak performance. Research on SPD film wear has shown promise, demonstrating the film's general dependability and endurance under a range of conditions.

5. Applications

When customizable transparency and interactive features are crucial, the versatility of PDLC technology is apparent. It has shown to be beneficial in creating dynamic and engaging environments in a variety of situations, including residences, workplaces, and medical facilities, as demonstrated by recent instances.

A combination of patient confidentiality and open contact has been made possible in healthcare contexts by the ability to modify transparency levels.

When quick switching between transparent and opaque states is required, SPD technology is applied. There is proof of its efficacy in reducing glare and improving comfort in automobile environments. Moreover, controlling light levels is perfect for galleries and museums.

FAQs

1.What Are The Main Differences?

The primary distinction is in the methods used to establish transparency control: Whereas SPD employs small particles responding to an electrical charge, PDLC uses liquid crystals affected by an electric current.

2.What's The Difference In Response Time?

With reaction rates of milliseconds, PDLC smart films offer effective privacy management. On the other hand, SPD technology alternates between states rapidly—in a few seconds.

3.Is Specialized Maintenance Necessary?

Almost minimal maintenance is needed for these smart films. Regular cleaning will help to get rid of dust and fingerprints. These technologies are reliable and robust in general.

4.What Benefits Do They Offer In Terms Of Usage?

While SPD technology is an excellent option for applications in automotive settings that demand speedy transitions, PDLC technology is ideal for surroundings that require interactive features and configurable transparency levels.

5.Is There A Significant Difference In Cost?

A number of factors, including application complexity, size, and customizability, may affect the pricing. SPD technology may be more expensive up front for some applications because to its rapid response capabilities.

English

English