What Is Non-adhesive PDLC Film

The original (standard kind) PDLC film is called non-adhesive PDLC film. Its primary purpose is to be sandwich laminated between two layers of glass to create a switchable PDLC glass product.

4 Features

● Liquid crystal polymers sandwiched between two ITO films make up PDLC Film, an electrically switchable film.

● To manufacture switchable PDLC glass, the film needs to be positioned between two layers of glass panels and is not sticky.

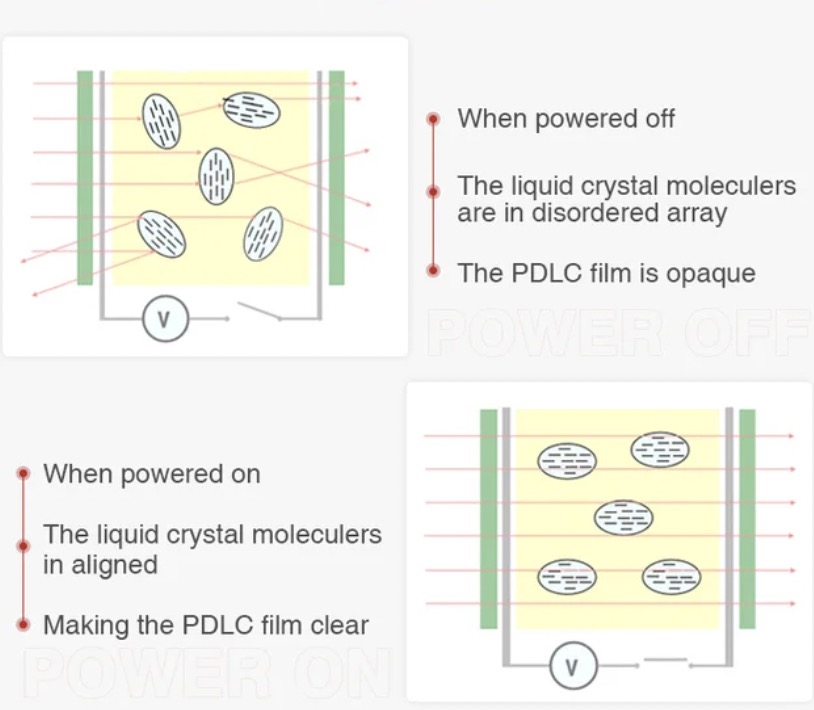

● You may convert the PDLC Film from clear to opaque by just flicking a switch.

● Cutting with scissors or a knife makes it simple to get custom sizes and shapes.

Self-Adhesive & Non Adhesive Smart Film - Which Is Best For You?

Self-Adhesive

Switchable Self-Adheisve Smart Film

Self Adhesive Smart Film for Doors

High Transparent Self Adhesive PDLC Film

Electronic Power Control Smart Film

Non Adhesive Smart Film

Laminated Smart Glass

Non Adhesive PDLC Film for Office/Window/Door

0.38mm Non-Adhesive Glass Film

Non Adhesive Smart Film Shower Room

Product Information

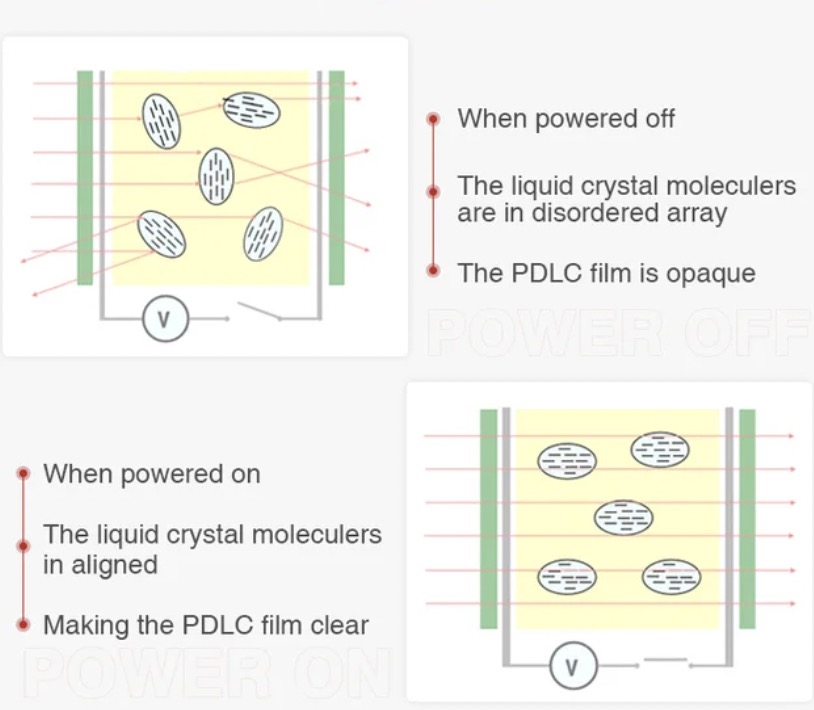

In order to make switchable PDLC glass products, the original type (standard type) PDLC film, also referred to as Non-adhesive PDLC Film, is typically sandwiched between two layers of glass. It is a transitional material that will be developed into the best switchable glass product possible. Other names for it include Magic Glass Film, PDLC Film, Privacy Glass Film, Smart Glass Film, Switchable Smart Film, and Electronic Film. When the electricity is turned on, it becomes transparent, and when it is turned off, it becomes opaque.

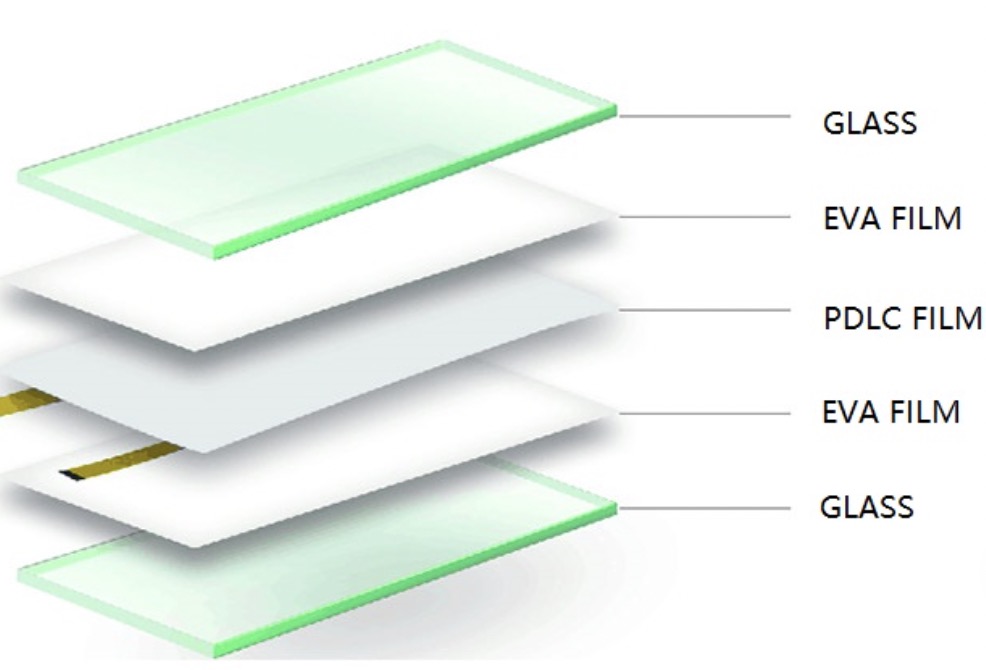

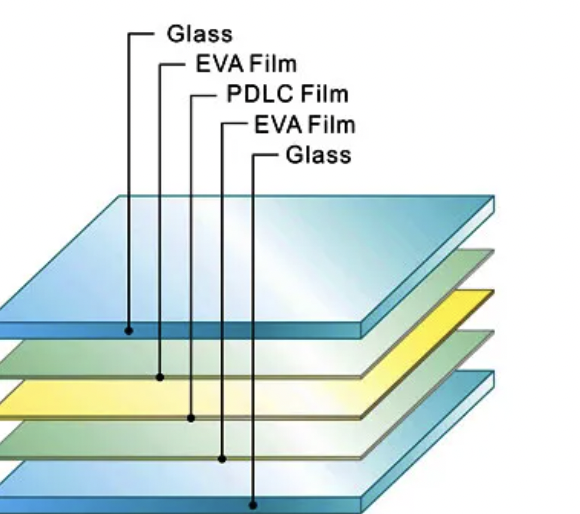

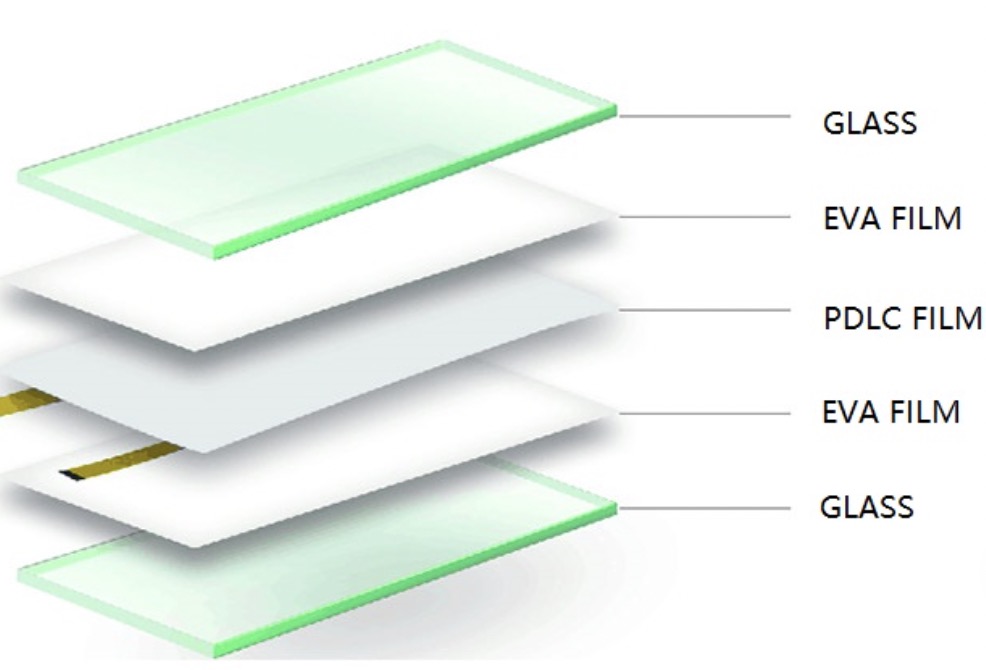

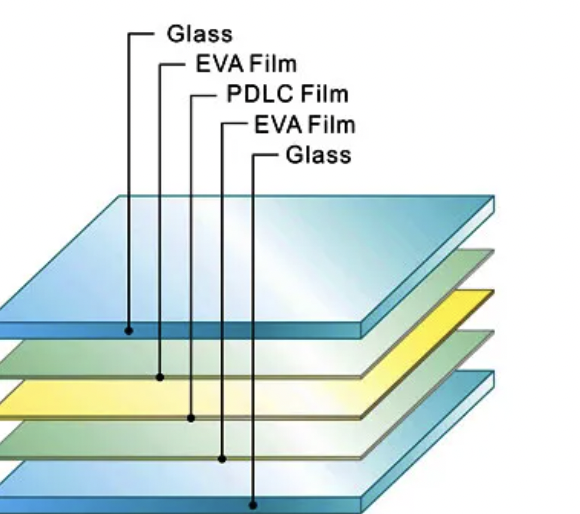

Product Configuration

• Glass

• Eva Film

• PDLC Film

• Eva Film

• Glass

Operating Principle

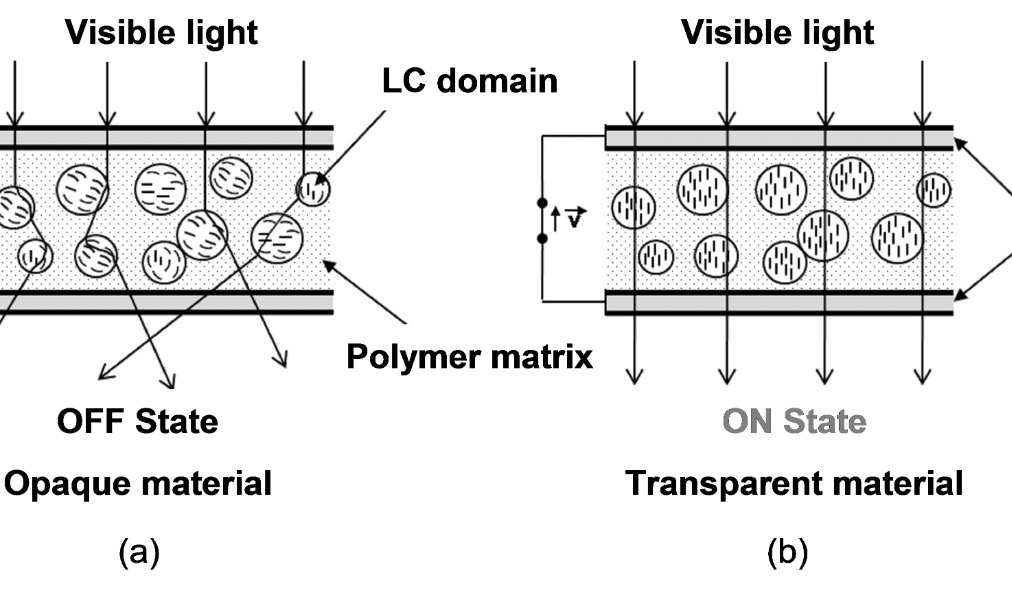

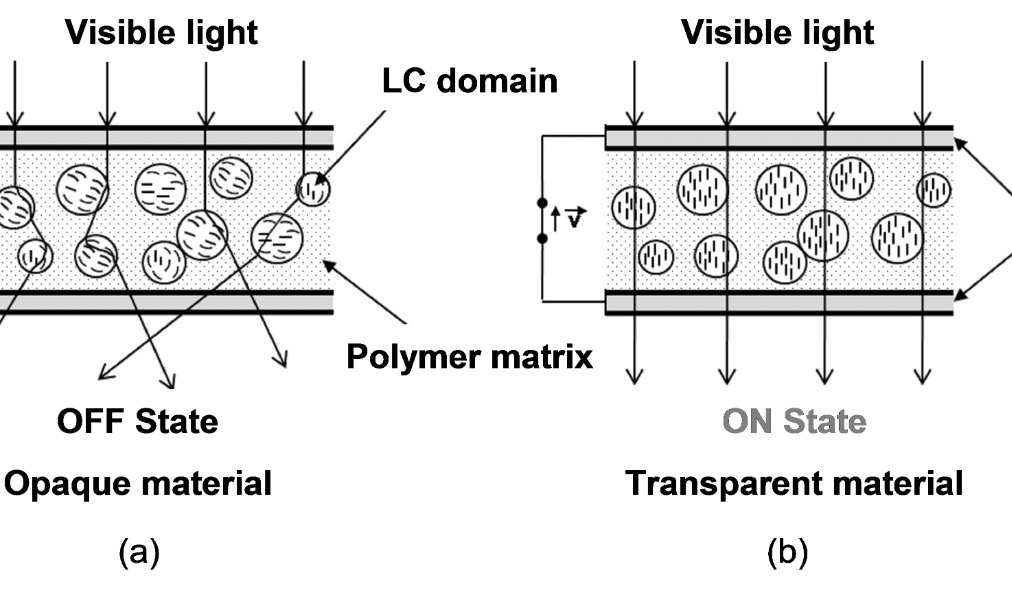

When an electric field is applied, a polymer dispersed liquid crystal (PDLC) layer may alter how light scatters. In the absence of electricity, visible light scatters across the PDLC, making the film opaque; in the presence of power, visible light passes through the PDLC, making the film transparent.

Technical Sheet For Product

Product Function | Status of power on: transparent |

| Status of power off: opaque |

| Parallel light transmission | (ON)>85% |

| OFF <1% |

| Transmittance of Visible Light | ON >86% |

| OFF >55% |

| Visual Angle | >150° |

| UV Blocking | OFF >99% /ON >75% |

| IR Blocking | OFF >65% /ON >20% |

| Haze | OFF >92% /ON < 4% |

| Using Voltage | 60 volts AC |

| Frequencies | 50 to 60Hz |

| Current | 100mA/m2 |

| Response Time | ON → OFF: 40ms |

| OFF → ON: 10ms |

| Power Consumption | POWER ON: 4W/m2/hr |

| Temperature | -30°C ~76°C |

| Storage Temperature | -45°C ~100°C/120°C (3H) |

| Service Life | Around 10 years (Power on) |

| Film Thickness | 0.38mm |

| Film Size in Roll | 1.2/1.5/1.8/2.0m*50m |

| Film Package Size | 1.5/1.8/2.1/2.3m*0.4m*0.4m |

| Gross weight of packaging | 45, 50, 55, and 60 kg |

Transparency Alters Linearly With Voltage

The voltage supplied will affect the transparency of the intelligent film; the closer to 0V, the less transparent it will be, and the closer to the Rated voltage (60V), the more clear and see-through it will become.

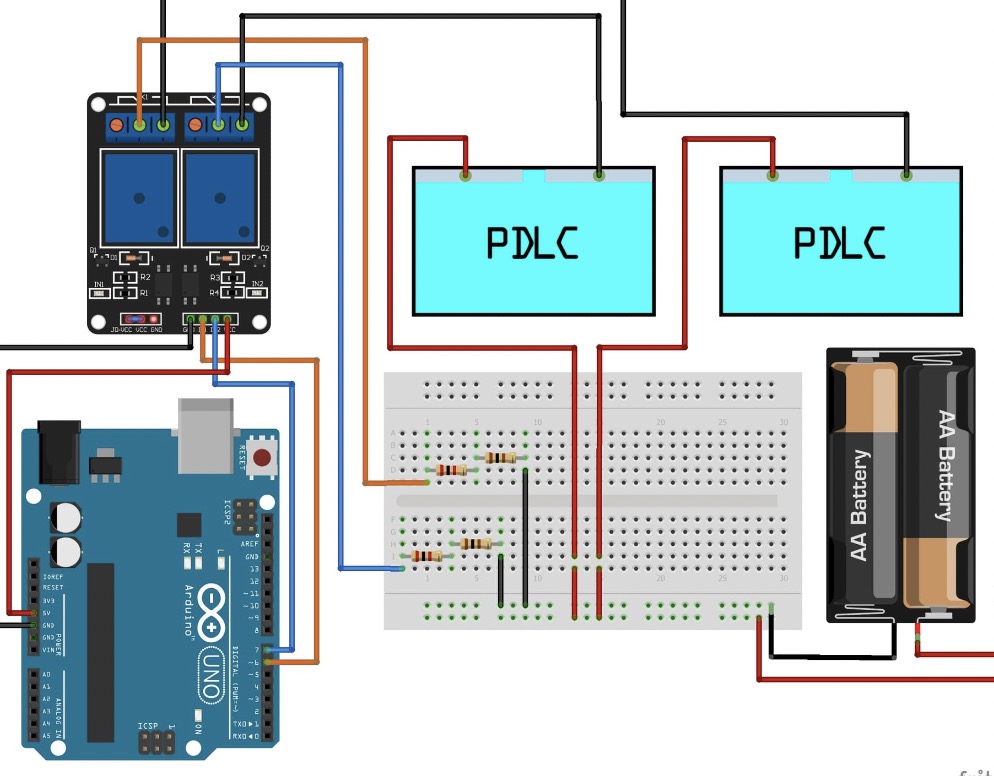

How To Create Smart PDLC Glass With PDLC Film Lamination

We advise utilizing non-adhesive smart film sandwiched between two glass layers for the best possible protection of the PDLC film and to maintain its longevity, particularly in high humidity situations.

Deciding to purchase our laminating smart film and having the finished goods (smart glass) manufactured by a local glass business. If there is no dealer nearby, this method lowers shipping costs and breakage risk compared to purchasing our pre-made glass.

Non-adhesive PDLC Smart Films Rolls Manufacturers

The reverse of the Non-Adhesive Smart Film has an electrostatic glue that makes it easy to stick to the existing glass. A simple ON/OFF switch turns the transparent film into an opaque one. typically seen on glass windows in monitoring centers, residential buildings, business buildings, and hotel toilets, among other places. People may enjoy both seclusion and open space with this clever privacy film.

6 Benefit Of Intelligent PDLC Film Rolls

1. Privacy and UV resistance In off state, resist 99.5% of UV radiation.

2. Multipurpose: offering energy conservation, cooling, privacy, shading, and environmental protection;

3. Energy-efficient, able to withstand 86.9% of heat radiation and save power

4. Wide range of applications: it may be applied on clear glass for indoor business or domestic use.

5. Simple setup. Simply peel and glue the busbar and wiring.

6. Extended lifespan: over a decade of use

A standard switch, touch switch, remote control, voice control, smartphone control, and more may all be used to operate Smart PDLC Glass. For convenient control, you may also link it to your smart home system.

• Wall switch

• Remote control

• Touch switch

• Dimmer control

• Magnetic switch

• Phone control

• Voice control

• Smart home control

Application Of The Product

- Frequently Used

• Residential

shower/bathroom enclosures, dividers

• Commercial

welcome areas, office doors and partitions, meeting rooms

• Retail

mirrors and projection screens

• Healthcare

Clinic Dividers, ERs, ORs, Nurseries, and ICU Doors

• Hospitality

shower/bathroom enclosures, walls

• Banking

secure deposit rooms, transaction windows, and ballistic teller lines

Video

Application Of Touchscreen And Projection

When in its opaque state, switchable PDLC glass functions well as a back projection screen. Touch screen capability is made possible by the use of an infrared touch frame with PDLC glass in conjunction with a rear projector, making this a ground-breaking tool for innovative concept presentation.

Our Feature PDLC Products

We now stock switchable PDLC glass, regular PDLC smart film (for lamination), and self-adhesive PDLC film (for glass adhesion), among other items.

Regular PDLC Film (Non-adhesive)

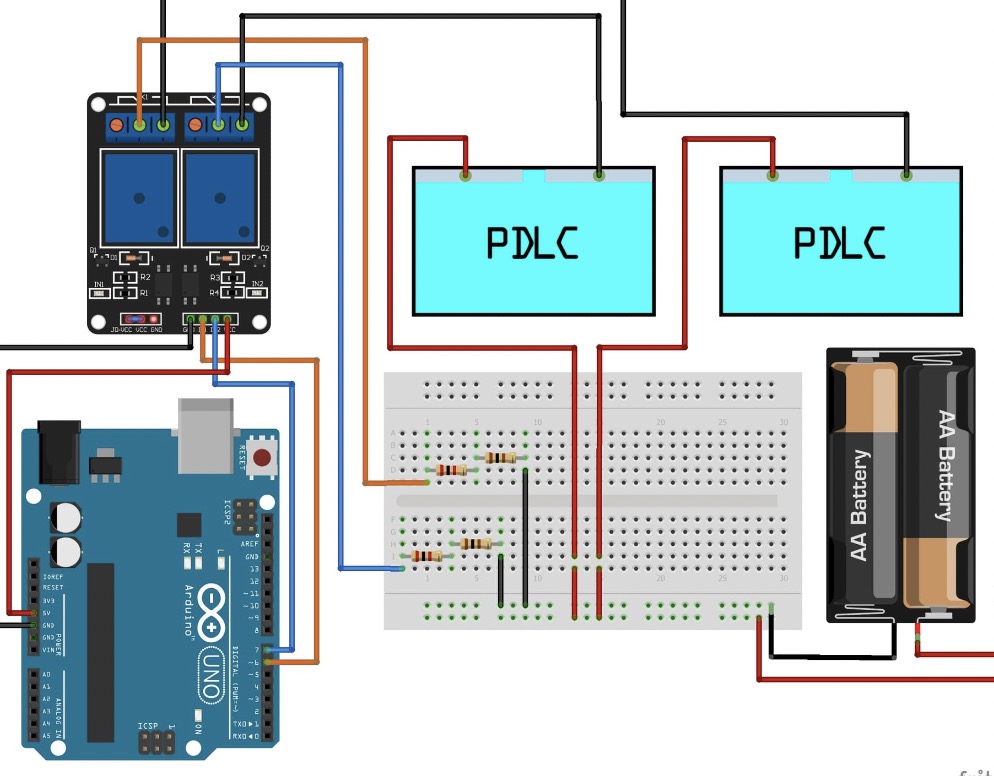

Liquid crystal polymers are layered between two layers of ITO films to create PDLC film, a form of film that can be electrically turned on and off. To convert this PDLC film into switchable PDLC glass, it must be sandwich laminated between two layers of glass panels.

Self-adhesive PDLC Film

A self-adhesive layer is applied to standard PDLC film to make the self-adhesive PDLC film. With its ability to be placed directly to glass surfaces, self-adhesive PDLC film is the ideal solution for smoothly converting ordinary glass into switchable smart glass.

Switchable PDLC Glass

A conventional PDLC film is layered between several glass layers to create switchable PDLC glass. Through the process of glass lamination, EVA film is used to attach the PDLC film to the glass layers. The material becomes translucent when the electricity is applied, and solid when it is removed.

English

English